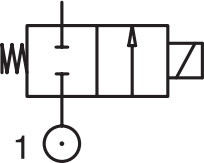

Solenoid Valve

EV250B, 2/2-way assisted lift operated solenoid valveEV310B, direct-operated 3/2-way solenoid valvesEV260B, servo-operated 2-way proportional solenoid valvesEV210B, 2/2-way direct-operated solenoid valvesEV224B, servo-operated 2/2-way solenoid valves for high pressureEV220B, servo-operated solenoid valvesEV210A, direct-operated 2/2-way compact solenoid valvesEV212B Solenoid valves with FKM isolating diaphragm 2/2-way direct-operatedEV220BW 15-50, indirect servo-operated 2/2-way solenoid valveEV228BW 15-50, indirect servo-operated 2/2-way solenoid valveEV220S 10-50 solenoid valveEV250BW 10-22, assisted lift operated solenoid valves for drinking waterEV221BW 10-22, direct operated 2/2-way

Solenoid valve

EV225B, servo-operated 2/2-way solenoid valvesEV220BW 15-50, indirect servo-operated 2/2-way solenoid valveEV228BW 15-50, indirect servo-operated 2/2-way solenoid valveEV210BW 1.5-6 solenoid valveEV250BW 10-22, assisted lift operated solenoid valves for drinking waterEV221BW 10-22, direct operated 2/2-way solenoid valve

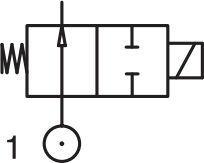

BRASS

PIPE MOUNTING

NORMALLY CLOSED

|

Port size |

Orifice Ø |

Flow factors |

Operating Pressure Differential |

Fluid Temp. |

Seat Seal |

Valve Ref. |

Housing Ref. |

Coil Ref. |

Power |

Coil Group |

Dwg. No. |

||||||

| KV | KV |

Qn |

Min |

Max(MOPD) |

|||||||||||||

|

BSP |

mm |

l/min |

m³/h |

l/min |

bar |

AC bar |

DC bar |

MIN °C |

MAX °C |

AC W |

DC W |

||||||

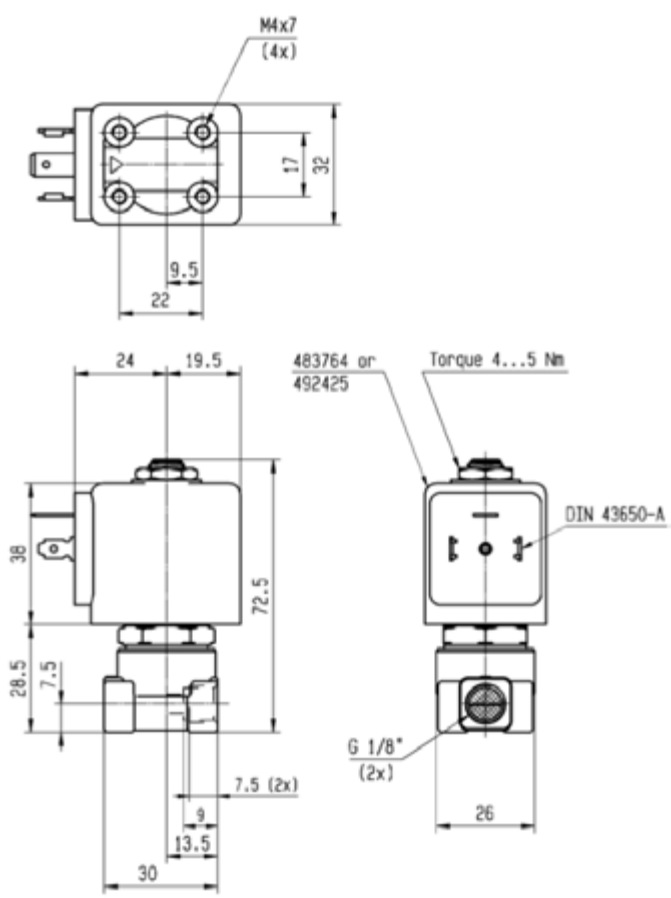

| 1/8" |

2.2 |

2.8 | 0.17 |

- |

0 | 25 |

- |

-10 | 120 |

Ruby |

121Z2323 |

299522 |

483764 |

9 |

- |

14.3 | 7863 |

| 3 | 4 | 0.24 | - | 0 | 30 | - | -30 | 160 |

Ruby |

121K2423 |

852023 |

483824 |

19 |

- |

14.1 | 3292 | |

| 1/4" | 3 | 4.5 | 0.27 | - | 0 | 30 | - | -30 | 160 |

Ruby |

121K6423 |

852023 |

483824 |

19 |

- |

14.1 | 3292 |

| 4 | 6.5 | 0.39 | - | 0 | 30 | - | 0 | 160 |

Ruby |

121K6220 |

852023 |

483541 |

20 |

- |

14.3 | 3510 | |

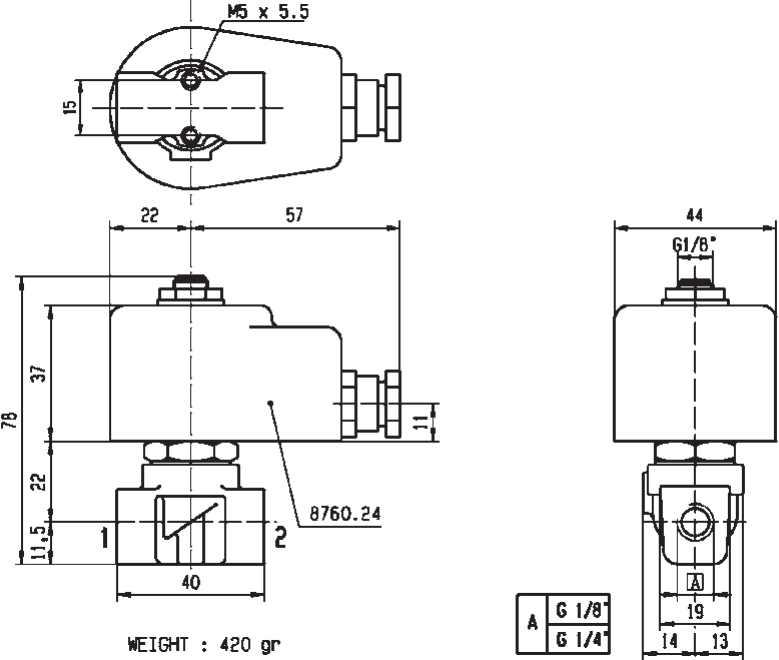

| 3/8" | 6 | 12 | 0.72 | - | 0 | 5 | - | 0 | 120 |

Ruby |

121K3321 |

2995 |

492425 |

14 |

- |

14.1 |

3551 |

| 11 | 22 | 1.32 | - | 0 | 30 | - | 0 | 160 |

FKM |

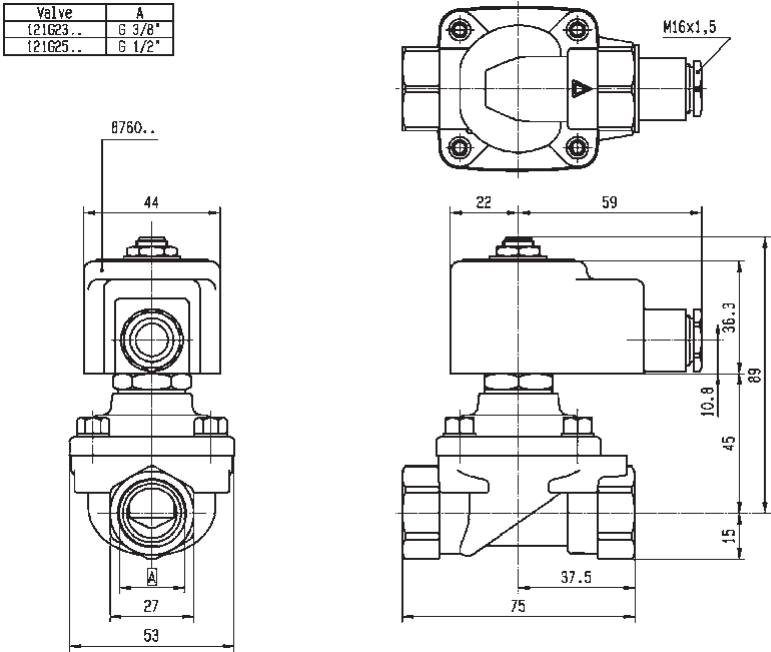

121G2320 |

852023 |

483541 |

20 |

- |

14.3 |

3646 |

|

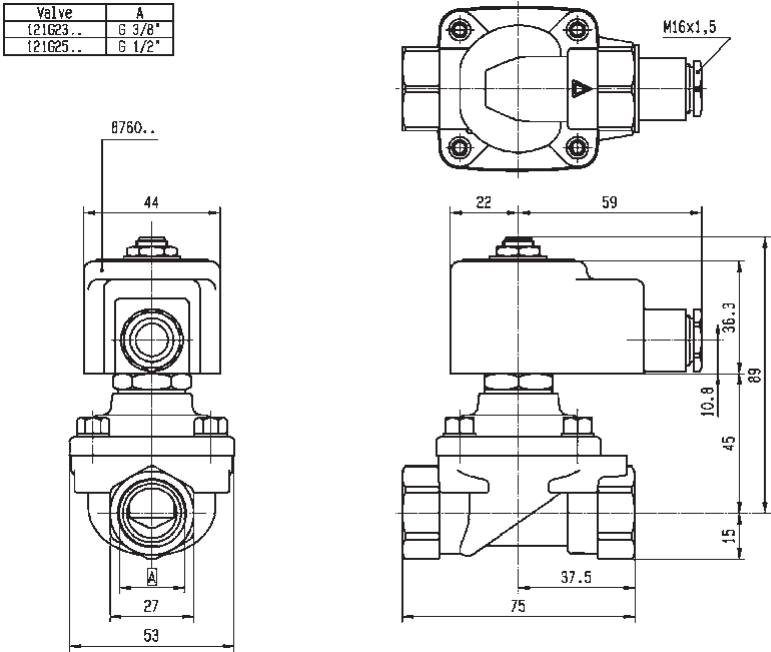

| 1/2" | 14 | 25 | 1.5 | - | 0 | 30 | - | 0 | 160 |

FKM |

121G2520 |

852023 |

483541 |

20 |

- |

14.3 |

3646 |

| 14 | 25 | 1.5 | - | 0 | 30 | - | 0 | 160 |

FKM |

121G2523 |

852023 |

483824 |

19 |

- |

14.1 |

3646 |

|

Notes:

1.DIN-EN-ISO 23553-1:2014-09 approved for oil burners

2.Max. Static pressure = 30 bar; max pressure differential = 0.2 bar

|

For this page |

Port size |

Orifice (mm) |

Kv (l/min) |

|

Fluid Temp |

|

From |

1/8“ |

3 | 4 | 5 | -30 |

| To | 1/2“ | 14 | 25 | 30 | 160 |

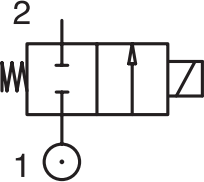

BRASS

PIPE MOUNTING

NORMALLY OPEN

|

Port size |

Orifice Ø |

Flow factors |

Operating Pressure Differential |

FluidTemp |

Seat Seal |

Valve Ref. |

Housing Ref. |

Coil Ref. |

Power |

Coil Group. |

Dwg. No. |

||||||

| Min |

Max(MOPD) |

MIN | MAX | ||||||||||||||

| KV | KV | QN |

AC |

AC | DC | AC | DC | ||||||||||

|

BSP |

mm |

l/min |

m³/h |

l/min |

bar | bar | bar |

°C |

°C |

Valve Ref. |

Housing Ref. |

W | W | ||||

|

1/8" |

2.5 | 3.5 | 0.21 | - | 0 | 30 | 0 | -30 | 160 |

Ruby |

122K9321 |

852023 |

483824 |

19- | 14.1 | 6766 | |

|

1/4" |

2.5 | 3.5 | 0.21 | - | 0 | 30 | 0 | -30 | 160 |

Ruby |

122K8321 |

852023 |

483824 |

19 | - | 14.1 | 6766 |

Notes:

1.DIN-EN-ISO 23553-1:2014-09 approved for oil burners

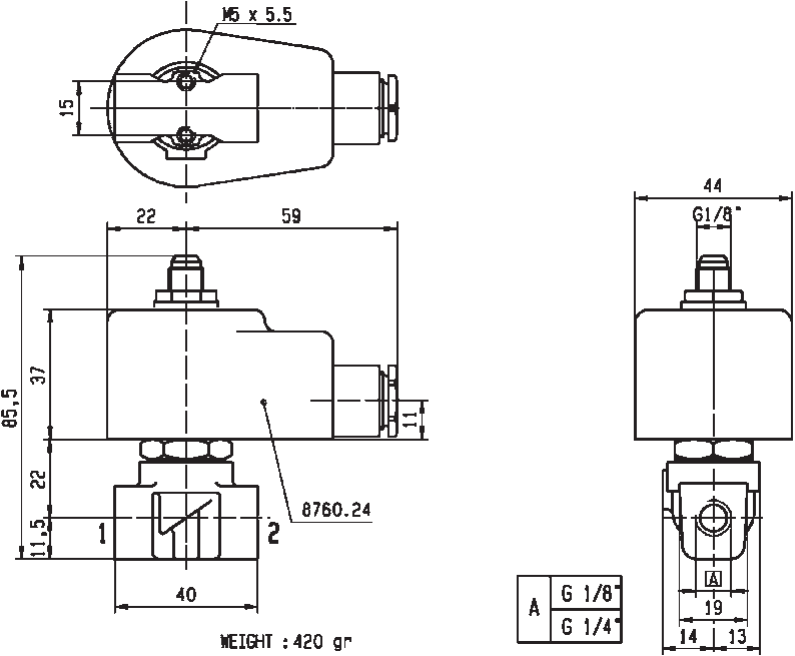

BRASS

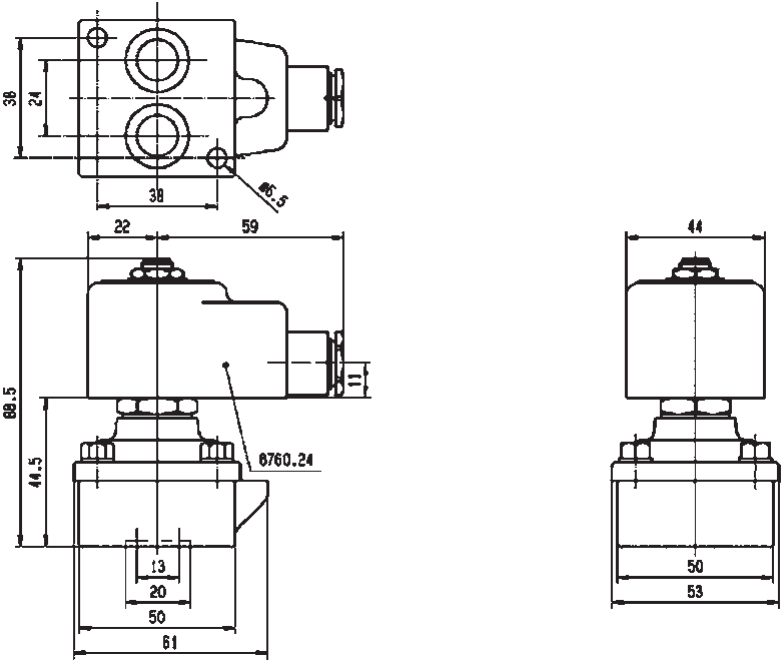

SUB-BASE MOUNTING

NORMALLY OPEN

Port size |

Orifice Ø |

Flow factors

|

Operating Pressure Differential | Fluid Temp |

Seat Seal |

Valve Ref. |

Housing Ref. |

Coil Ref. |

Power |

|

Dwg. No. |

||||||

| Min |

Max(MOPD) |

MIN | MAX | ||||||||||||||

| kv | 1.5 |

Qn |

AC | DC | AC | DC | |||||||||||

| mm |

l/min |

m³/h |

l/min |

bar |

bar |

bar |

°C |

°C |

W | W | |||||||

| SB | 14 | 23 | 1.5 | - | 0 | 30 | - | 0 | 160 | FKW |

121F2523 |

852023 |

483824 |

19 | - | 14.1 | 7638 |

Notes:

1.DIN-EN-ISO 23553-1:2014-09 approved for oil burners

|

For this page |

Port size |

Orifice (mm) |

Kv (l/min) |

|

Fluid Temp (°C) |

|

From |

1/8" |

2.5 | 3.5 | 30 | -30 |

|

To |

SB | 14 | 25 | 30 | 160 |

PRODUCT